BADA’s production capacities:

-50, 000 tons of primary magnesium

-40, 000 tons of alloyed magnesium

-25, 000 tons of DC billets

-30, 000 tons of semi-fabricated magnesium products

-20, 000 tons of alloyed aluminum

-30, 000 tons of aluminum extrusion

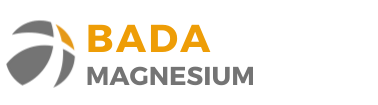

In BADA’s industrial sites are operating:

-Dolomite Calcination

-Thermal Reduction

-Smelting and Refining

-Direct Chill Casting

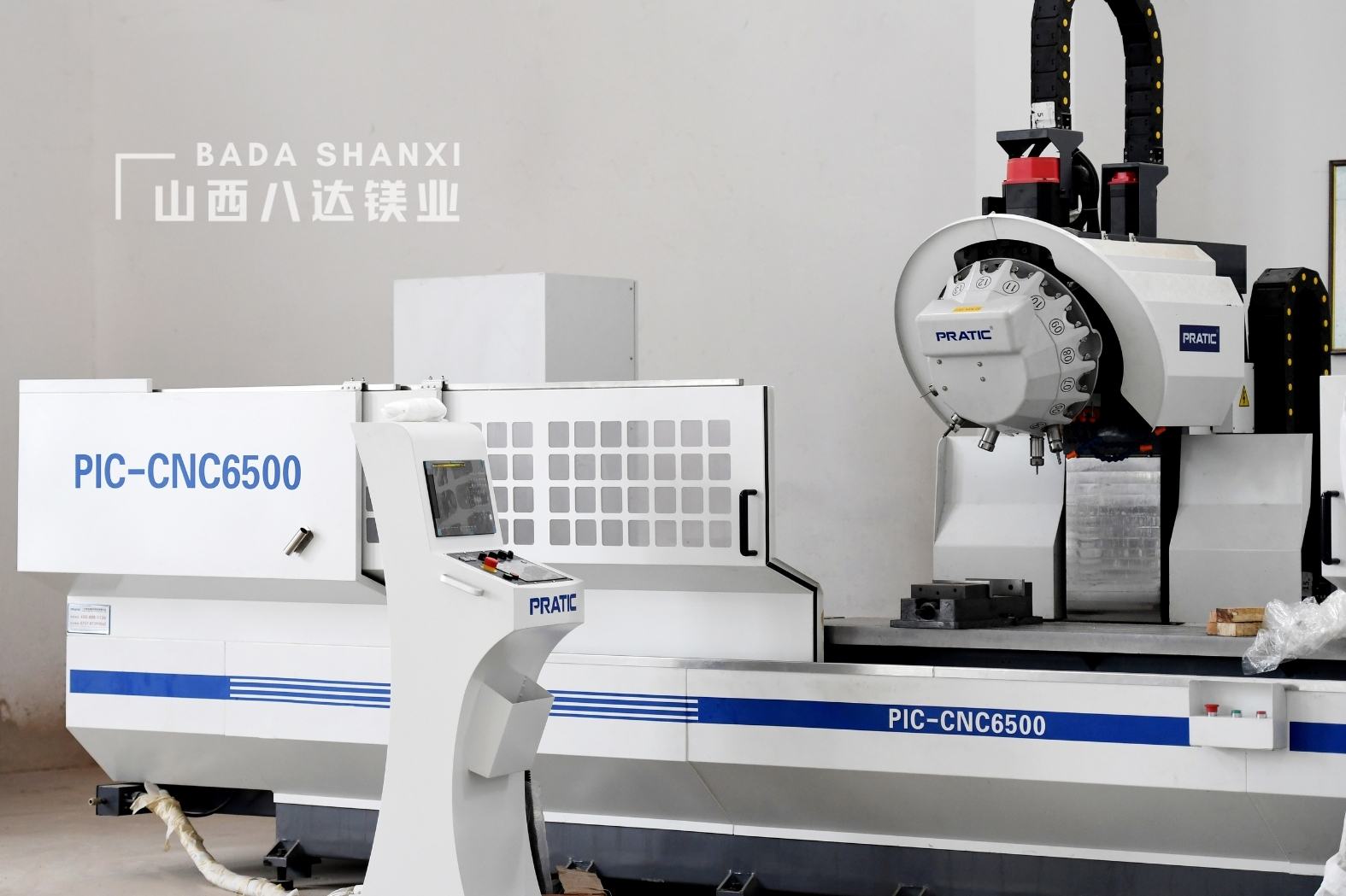

-Extrusion

-Rolling

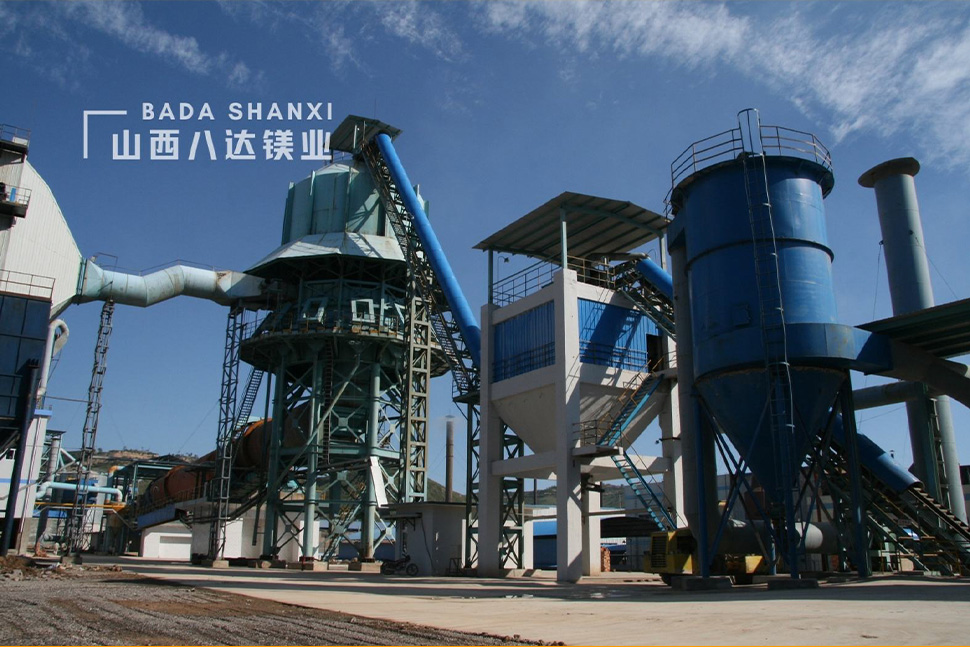

-Casting

-Fabrication & Coating